PUF SLABS | PIPE SECTIONS

PU FOAMS

PU Slabs: These are made to standard size of 1000 mm X 500 mm, 1000mm x 1000mm, 4’ x 4’ and a special size in various thickness ranging from 5 mm to 500 mm and density ranging from 34Kg ±2Kg/Cu.M to 60 Kg ±2Kg/Cu.M. We offer customised corrugated sheets as per customer profile. Used for various applications in cold storage. Cold plants, freezers, false ceilings etc.

PU Pipe Section: To Suit 12mm NB to 750 mm NB Wall thickness ranging from 15 mm to 300 mm STD. Length: 1000mm. Specific dimensions can be made to order. Pipes are made in the form of half round x 1000mm long to suit various Nominal bores of Pipe lines for insulation purposes.

We offer pipe sections to the size of 750 mm dia of various thicknesses and beyond that we offer lag sections from 1 mtr dia to 4 mtr dia.

PU Saddle/Supports: These type are used for supports for the pipeline, we offer anchor type, slide type and guide type supports for pipes from 15mm to 750mm NB for various thickness of insulation and density ranging from 60 - 300 Kg/Cu.M.

PU Lags Section: Lag sections are specially moulded for larger diameter / radius shells tanks etc. to suit the curvature of the tanks or shell, these sections are suitably made and are layered one upon the other to increase the thickness of the insulation by staggered joints. This method is useful in the absence of thin insulation - pouring/foaming and to prevent blowholes or unfilled area by insitu foaming method of insulation.

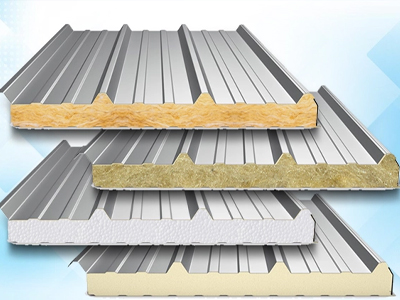

PU Panels (Sandwich Panels): Cold rooms are designed for Hotels, Catering Firms, Retail Stores, Pharmaceutical Companies, Hospitals and Supermarkets, Cold Storages, for the storage of food & beverage. They can also be used for Preparation Rooms, Laboratories, Industrial Premises & Telecom Shelters.

With its modular, prefabricated PUF insulated panels, the cold rooms can be extended in three directions (height, width and depth), offering a very large number of volumetric combinations.

Physical Properties of PU Foam

- Density: 38 ±2 kg/Cu.M.

- Comprehensive Strength: 280 KPa

- Tensile Strength: >1.8 kg/cm² (ASTM 1621-64)

- Close Set Content: >95%

- Thermal Conductivity (K): 0.018 W/m deg K

- Ignitability (ASTM D 1699): Fire retardant, not easily ignitable (Class P)

Technical Specifications for PUF / PIR Boards & Pipe Sections

| PROPERTIES | POLYISOCYANURATE (PIR) | POLYURETHANE FOAM (PUF) |

|---|---|---|

| Density | 40 ± 2 kg/m³ higher density available | 36 ± 2 kg/m³ higher density available on request |

| Compression Strength (In Direction Of Rise) | 172 kN/m² (1.75 kgf/cm²) | 172 kN/m² (1.75 kgf/cm²) |

| Thermal Conductivity 'K' (initial at 100°C) | Max 0.021 W/mk (0.15 BTU-in/hr.sq.ft.degF) | Max 0.021 W/mk (0.15 BTU-in/hr.sq.ft.degF) |

| Temperature Limit | 150°C – 180°C | 110°C – 160°C |

| Fire Resistance Properties | Class 'P' (Not Easily Ignitable) Less than 125 mm | Class 'P' (Not Easily Ignitable) Less than 125 mm |

| Closed Cell Content | 90% (Min.) | 90% (Min.) |

Available Size

- Boards 1m x 0.5m

- Pipe-Section to suit 15 NB to 750mm NB x 1m long.

- Other sizes available on request.

- Custom moulded shapes to suit Horton spheres and Lag -sections.

- Boards 1m x 0.5m

- Pipe-Section to suit 15 NB to 750mm NB x 1m long.

- Other sizes available on request.

- Custom moulded shapes to suit Horton spheres and Lag -sections.

PUF Supports are made from specially formulated chemical system that results in the most adaptable material with several advantages. Higher densities enable higher loads without increase in surface area. Lower densities can be used for lighter loads resulting in significant cost saving.

Physical Properties for Different Densities

| Density (Kg/m³) | Closed Cell % | Water Vapour Transmission (gms/m²/24hrs) | Compression Strength (KPa) | Tensile Strength (KPa) |

|---|---|---|---|---|

| 60 | 95 | 50 | 900 | 1200 |

| 120 | 94 | 45 | 1500 | 2000 |

| 180 | 92 | 40 | 2000 | 2500 |

| 240 | 91 | 36 | 3000 | 3500 |

| 320 | 90 | 18 | 5000 | 5000 |